To start with, GD&T symbols are standardized and specified in the ASME Y14.5 requirement, which means they have global acceptance in design self-controls. Each symbol shares specific info pertaining to the tolerance applied to a function. As an example, symbols for monotony, circularity, straightness, and cylindricality depict the allowed variance from the ideal geometric form. Monotony, stood for by a two-dimensional sign, makes sure that a surface area is uniformly flat within defined restrictions, which is vital for surface areas that require to secure or mate. Understanding and applying these symbols properly can assist stop mismatches and setting up issues, improving product reliability.

Discover GD&T symbols and guidelines the value of Geometric Dimensioning and Tolerancing (GD&T) in engineering and manufacturing, as it enhances communication, accuracy, and cost-efficiency while decreasing mistakes with standardized symbols and guidelines.

In enhancement to form controls, GD&T likewise consists of positioning controls, such as angularity, parallelism, and perpendicularity. Recognizing exactly how to specify and translate these orientation symbols is pivotal for specific manufacturing and top quality engineering.

Location regulates such as symmetry, concentricity, and position are also crucial elements of GD&T. Discovering to use these area symbols effectively will aid designers in achieving useful components that satisfy design requirements while additionally simplifying the manufacturing procedures included.

An additional important element of GD&T is the idea of datums, which are recommendation points or surface areas that act as a basis for dimension. The effective use of datums is essential in guaranteeing regular manufacturing high quality. Each information is appointed a letter classification, and it anchors the component to sector requirements, making sure that dimensions are repeatable and reputable. Appropriately defined information allow engineers to manage variations extra properly, lowering the possibility of errors in production. These recommendations assist in establishing a durable coordinate system that all resistances can associate back to, making it necessary for any kind of design engineer to have a firm grasp of how to build and make use of datum references.

When a developer specifies resistances utilizing GD&T symbols, it reduces the obscurity commonly connected with traditional dimensioning techniques. In industries where accuracy and high quality are paramount, such as aerospace or clinical device production, the function of GD&T in streamlining interaction can not be overstated.

Additionally, the application of GD&T is valuable for price efficiency in production. By defining resistances a lot more accurately, designers can enhance layouts to utilize materials and procedures much more successfully. By specifying larger tolerances where limited tolerances are unneeded, suppliers can utilize much less costly machining methods, conserving both time and cash while still maintaining the integrity of the last product. This effective approach helps minimize waste and decreases manufacturing expenses, which is essential in today's open market. Engineers that understand GD&T can substantially influence the cost-effectiveness of their styles without sacrificing top quality or efficiency.

Nonetheless, despite its benefits, implementing GD&T can be intimidating for those strange with the system. Wrong usage can cause costly errors in production and setting up, making correct training in GD&T principles vital. Numerous instructional resources, workshops, and training courses are currently readily available to assist developers and designers find out the nuances of GD&T. Such training typically stresses the importance of not only recognizing the symbols yet additionally being able to apply them to real-world design scenarios. Practical applications of GD&T in situation research studies can provide understanding right into how properly executed symbols cause boosted quality and minimized scrap prices in production.

When editing or interpreting engineering drawings that utilize GD&T, attention to information is paramount. Standardization advertises a society of high quality and consistency, strengthening the value of GD&T principles in daily design method.

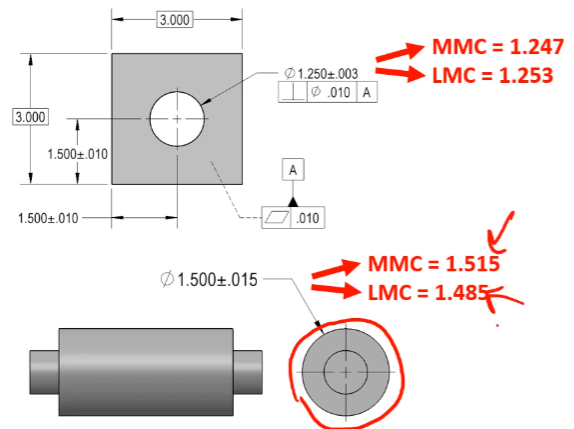

Discover mmb vs mmc the significance of Geometric Dimensioning and Tolerancing (GD&T) in engineering and manufacturing, as it enhances interaction, accuracy, and cost-efficiency while decreasing mistakes via standard symbols and guidelines.

In conclusion, mastering GD&T symbols and guidelines is a vital skill for modern-day designers, particularly those involved in layout and production. By spending in correct training and exercising the reliable application of GD&T concepts, designers can utilize this effective device to drive technology and excellence in their layouts, inevitably leading to a much more successful and competitive item development lifecycle.